Blog

Pro-Active Engineering Sharpen the Saw

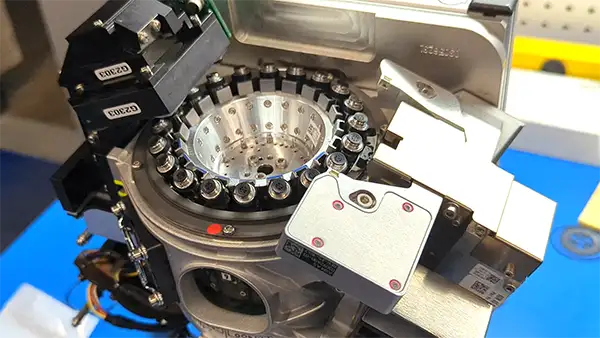

Sharpening the Saw = Maintaining Peak Performance! Our ASM SIPLACE TX keeps flying with routine maintenance. Look at that 20-nozzle CP20 head gleaming! www.proactivepcb.com

Read MoreEmployee Spotlight at Pro-Active Engineering

🌟Employee Spotlight: Lorina!🌟 WHAT IS YOUR ROLE AT PRO-ACTIVE ENGINEERING? As the Production Manager I’ve had the pleasure to work with our dynamic and talented departments throughout the office and plant. We have many work orders moving within the day-to-day activities, and making sure items keep moving to meet our customer’s demands. There are days…

Read MorePro-Active Engineering New Hires

🚨 New Teammates Alert! 🚨 It is with great excitement that we introduce the following fantastic individuals who have joined our team: Lisa, Brenda, Harold, Dorian, Jules, Robert, Tiana and Chanhia. We are thrilled to have you on board and look forward to working together. 👏 www.proactivepcb.com

Read MoreSomething BIG

Something big is coming! We’re super excited to unveil some game-changing new equipment at Pro-Active Engineering! Coming soon… www.proactivepcb.com

Read MorePCBA Manufacturing Process Flow

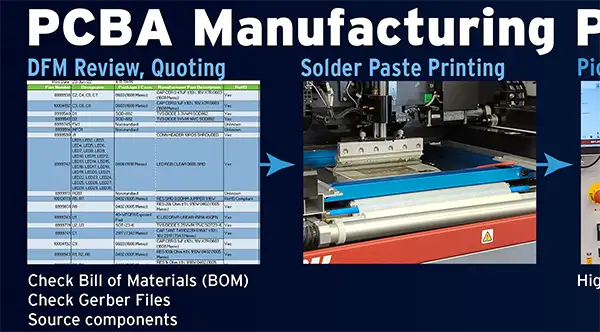

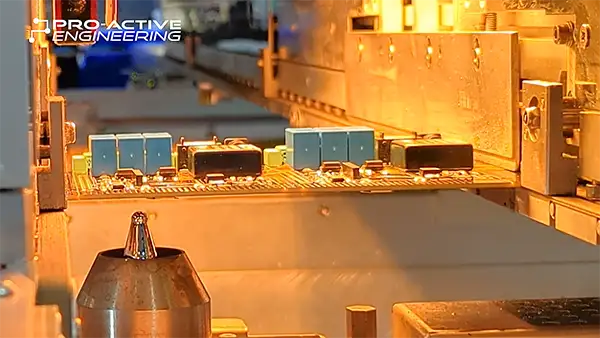

Untangle the magic of PCBA manufacturing! We break down the steps from design to delivery at Pro-Active Engineering. Learn more: www.proactivepcb.com

Read MoreReshore at Pro-Active Engineering

Time to bring it home? Reshoring offers: • SUPPLY CHAIN SECURITY: Control your production & avoid disruptions. • QUALITY YOU CAN TRUST: Build with US expertise & manufacturing. • FASTER TIME_TO_MARKET: Streamline production & get your project out quicker. Is reshoring right for you? Pro-Active Engineering can help! www.proactivepcb.com

Read MoreEngineering Excellence from Pro-Active Engineering

Packed house for PCB Stack up & Cost Control Engineering Excellence! Our seminar with Ryan Miller & Mike Marshall (NCAB Group) was a hit! Attendees learned about stack-up, impedance, and cost drivers, plus enjoyed treats, lunch, and a 3D printer giveaway! Following lunch many guests enjoyed a tour of Pro-Active Engineering facility. Stay tuned for…

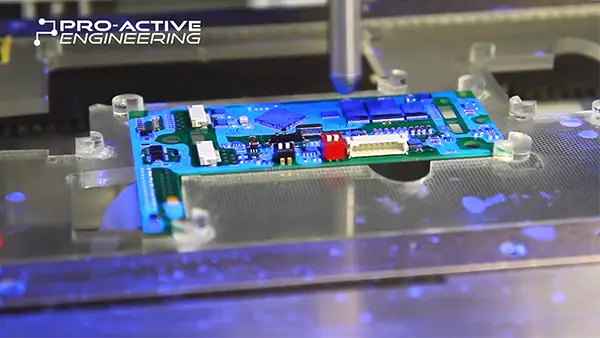

Read MoreConformal Coating at Pro-Active Engineering

Conformal Coating: Beauty meets brilliance. Our advanced robot & custom programming deliver precise, flawless protection for your electronics. Let Pro-Active be your shield. www.proactivepcb.com

Read MoreEmployee Appreciation Day 2024

Cheers to our incredible team! Today, and every day, we celebrate the dedication and hard work that makes Pro-Active Engineering successful. Thank you for being the engine that drives our achievements! www.proactivepcb.com

Read MoreEngineering Excellence

Event Registration Join Pro-Active Engineering and NCAB Group for our first Engineering Excellence event of 2024: PCB Costs and Key Trends to Consider Session 1: Stack-up & Impedance / PCB Trends Ryan Miller, NCAB Group A look at technical challenges and future trends to understand the obstacles, anticipated developments and key factors propelling technical progress in…

Read More